SUPPLIERS

AEROENGINES

WE [AIR] INDUSTRY

Back to the origins

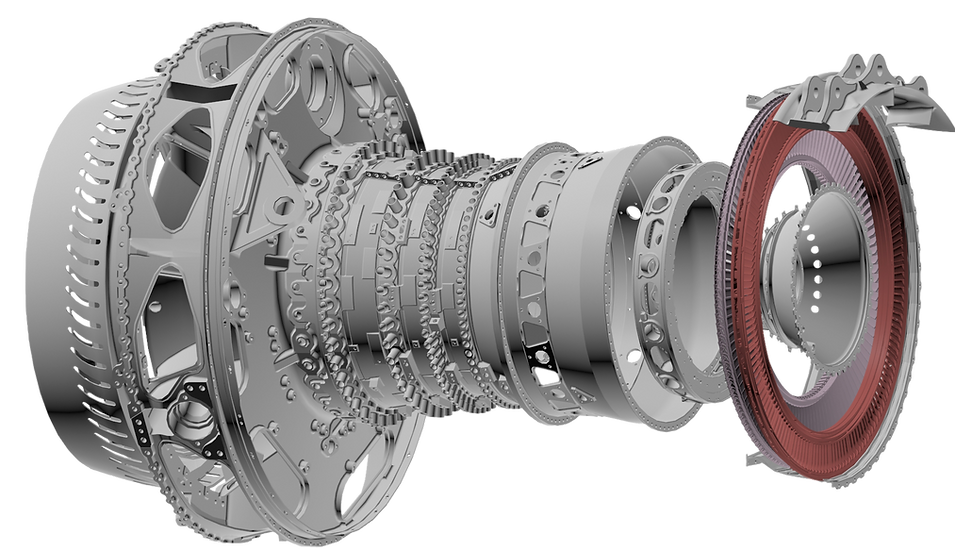

Since 1984, at Aeroengines we have been designing and manufacturing high-tech components for aircraft engines and industrial turbines, providing solutions that combine innovation, quality and commitment.

As a business unit of Aciturri, a family-owned company founded in 1977, we combine decades of experience with a clear focus on operational excellence and global competitiveness. Our services focus on ensuring agile and efficient industrialisation processes, for which we have a highly qualified team.

We are defined by technological innovation, but also by a firm commitment to our environment, focusing on sustainable relationships and industrial development that respects people and the planet.

Innovative You

Can't Ignore

Manufacturing technologies

Multi tasking machining.

3 & 5 Axis grinding.

Wire & Sinker EDM.

Fast drilling EDM.

Honeycomb Manufacturing.

Additive Manufacturing.

Hand Lay Up.

Resin Transfer Moulding (RTM).

Special processes

Plasma Spray Coating.

APVS.

Heat treatment & Brazing.

TIG Welding.

Sacrificial Painting.

Functional Testing.

Mechanical Assembly.

Inspection technologies

3D Control.

Digital X-Ray.

FPI.

Ultrasonic inspection.

Supercleaning.

INDUSTRIAL EXPERTS

40 years’ experience in aerospace programs

PARTNERS TO SUCCESS

Financial solvency and capacity for risk-shared programs

RESPONSE AND CONFIDENCE

Comprehensive management, competitiveness and service

Innovation

The Company is also developing a Technology Plan to offer the market advanced bonding solutions, ceramic matrix composites and artificial intelligence.

For example, since late 2023, Aciturri Aeroengines has been working on implementing new production processes for aircraft engine components that prevent waste generation. These are joining processes and surface treatments that, on the one hand, guarantee and improve a series of physical and mechanical properties such as strength, surface hardness, and resistance to wear and corrosion of the components, and on the other hand, facilitate their remanufacturing.

This project, entitled ‘NEW SURFACE TREATMENT TECHNOLOGIES FOR A STATE-OF-THE-ART CIRCULAR COMPONENTS INDUSTRY’ and known by its acronym TITAN, has been proposed as an inter-sector collaboration with the companies Finanzauto S.A. and Flubetech S.L., with Aciturri Aeroengines acting as coordinator.

The TITAN project is a beneficiary of the call for grants to promote the circular economy in companies for 2022 from the Ministry for Ecological Transition and Demographic Challenge (MITECO) within the framework of the Recovery, Transformation and Resilience Plan (PRTR) financed by the European Union – NextGenerationEU.

Clients

TRUST - SOLUTIONS - DEVELOPMENT

We build close, transparent and reliable relationships.

Adding value and solutions throughout the whole supply chain.

Contributing to the strengthening of the global aerospace industry.

Siemens

Leader in technology focused on industry, infrastructure, mobility, and health. Combines the real and digital worlds to accelerate digital and sustainable transformation.

GE Aviation

Leading manufacturer of jet and turboprop engines,

components and integrated systems for commercial, military and business aircraft.

Airbus

European company that designs, manufactures and sells civil aircraft, a subsidiary of the Airbus SE conglomerate.

PLD Space

A pioneering Spanish aerospace company and a European leader in the development of reusable launchers, with a proven track record in the sector and a robust development programme.

Safran Landing System

The world leader in aircraft landing and braking systems. From design and development to production and support.

ITP Aero

The power of talent. One of the Top 10 aerospace engine and components companies in the world.

.png)

Safran Aircraft Engines

International high- technology group and Tier 1 supplier of systems and equipment in the Aerospace and Defense markets.

Rolls-Royce

One of the world’s leading producers of aero engines for large civil aircraft and corporate jets. The second largest provider of defence aero engines in the world.

Siemens

Leader in technology focused on industry, infrastructure, mobility, and health. Combines the real and digital worlds to accelerate digital and sustainable transformation.

GE Aviation

Leading manufacturer of jet and turboprop engines,

components and integrated systems for commercial, military and business aircraft.

Airbus

European company that designs, manufactures and sells civil aircraft, a subsidiary of the Airbus SE conglomerate.

PLD Space

A pioneering Spanish aerospace company and a European leader in the development of reusable launchers, with a proven track record in the sector and a robust development programme.

Certification

Quality is our past, present and future. Aciturri assumes the commitment to continuously improve the quality and safety of the products and services the company provides to its clients. The Quality Policy, shared by the whole organization, includes as pillars that sustain this commitment the permanent search of excellence, the active collaboration with clients and subcontractors, staff training and the continuous improvement.

In the same way, Aciturri guarantees that both its quality systems and processes meet comprehensively to the industrial, operational and corporate requirements of both the aerospace sector and our customers.

EN 9100:2018 | DNV

EN 9110:2015 | AENOR

ISO 9001:2015 | DNV

UNE·EN·ISO/IEC 17025 | ENAC

ISO 14001:2015 | DNV

ISO 45001:2018 | DNV

PECAL·AQAP 2120 | DGAM

PECAL·AQAP 2110/2310 | DGAM

NADCAP ACCREDITATIONS

-

NON-CONVENTIONAL MACHINING

-

WELDING

-

END

-

CHEMICAL PROCESSES

COMPOSITES

.jpg)

EXPERT PROFESSIONALS

WHO LOVE

OUR PROFESSION

Management Team

OUR ECOSYSTEM

Building and sustaining our own corporate culture is essential to guarantee the fulfilment of our commitments, as well as to grow in a sustainable and long-term way.

This is the mission of our company, which is led by an executive team fully committed to the industry and to give the best of themselves.

.png)

Where we are